Developed in 1910 by Westinghouse Electric Corporation as an industrial thermo-set laminate for electrical insulation, Micarta is known for being "The Steel of the Plastic Industry".

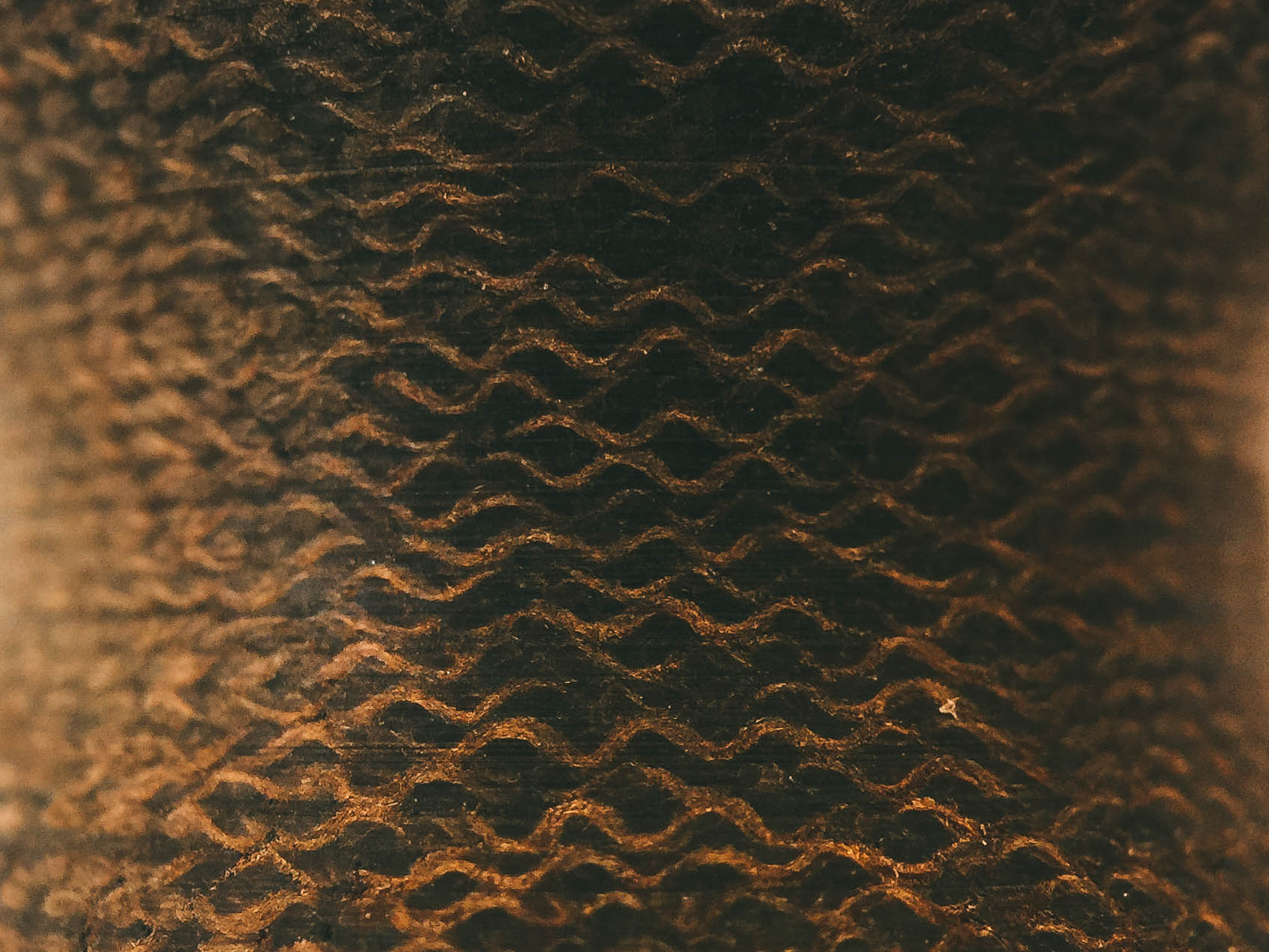

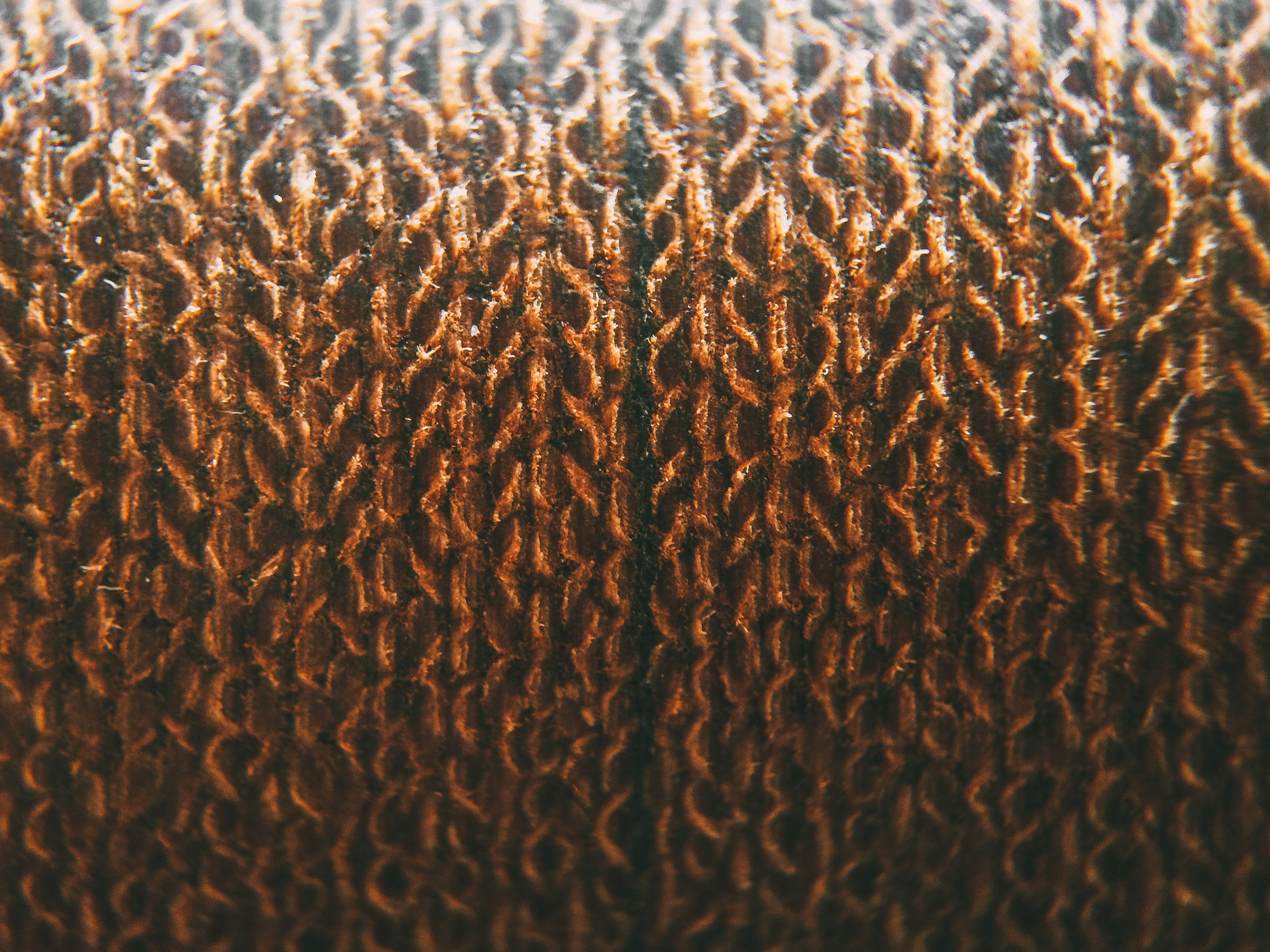

Made of fiberglass canvas, linen or paper layers which were soaked in phenolic resin, then baked and pressed into large sheets, tubes or rods of varying thicknesses. Micarta is a hard, compact composite material that will not warp, expand or shrink with age and exposure to the weather.

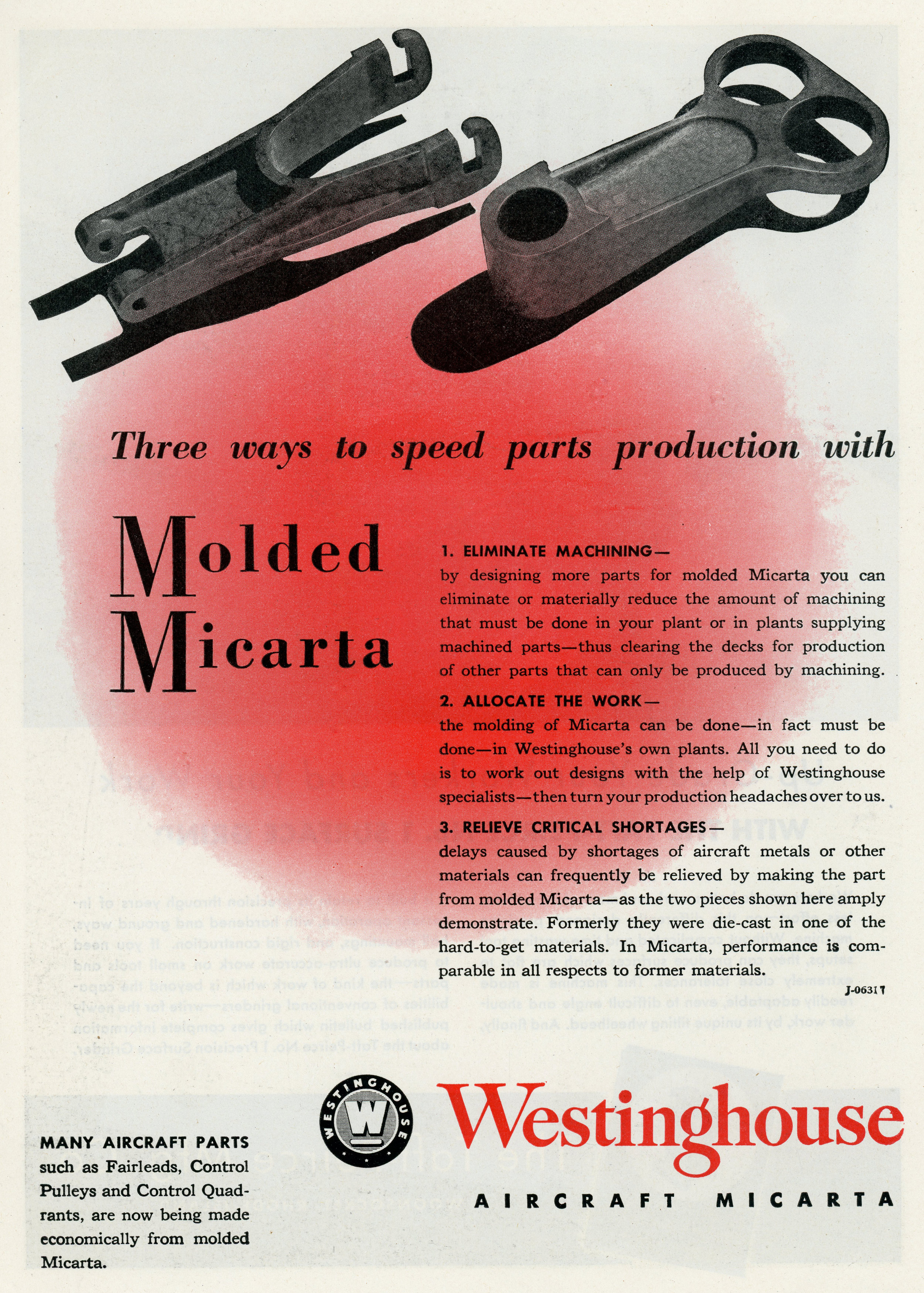

With the finishing of the moulded material plant many different articles will be made from Micarta, a light, strong compound material. Westinghouse engineers who developed the material are busy discovering new uses for it although thousands are already known. Micarta is used to make airplane propellers that will not shatter, airplane pulleys that won't flatten and make the plane hard to handle, silent street railway gear wheels, and to make many other products where a material of lightness and strength is needed.

In order to give the Micarta propellers the most strenuous test possible the Westinghouse Company has built a test building. Here propellers are rotated at high speeds by a 400-horsepower electric motor.

The propeller turns in a constant stream of artificial rain which severely tries the strength of the material. In addition the propeller is made to "flutter" as it would in actual use on an airplane ill order to test its resistance to vibration. This test is carried on in a sound-proof build- ing where the fierce blasts of air and the continued roar are effectively pocketed. Otherwise the sound would be heard miles in all directions.

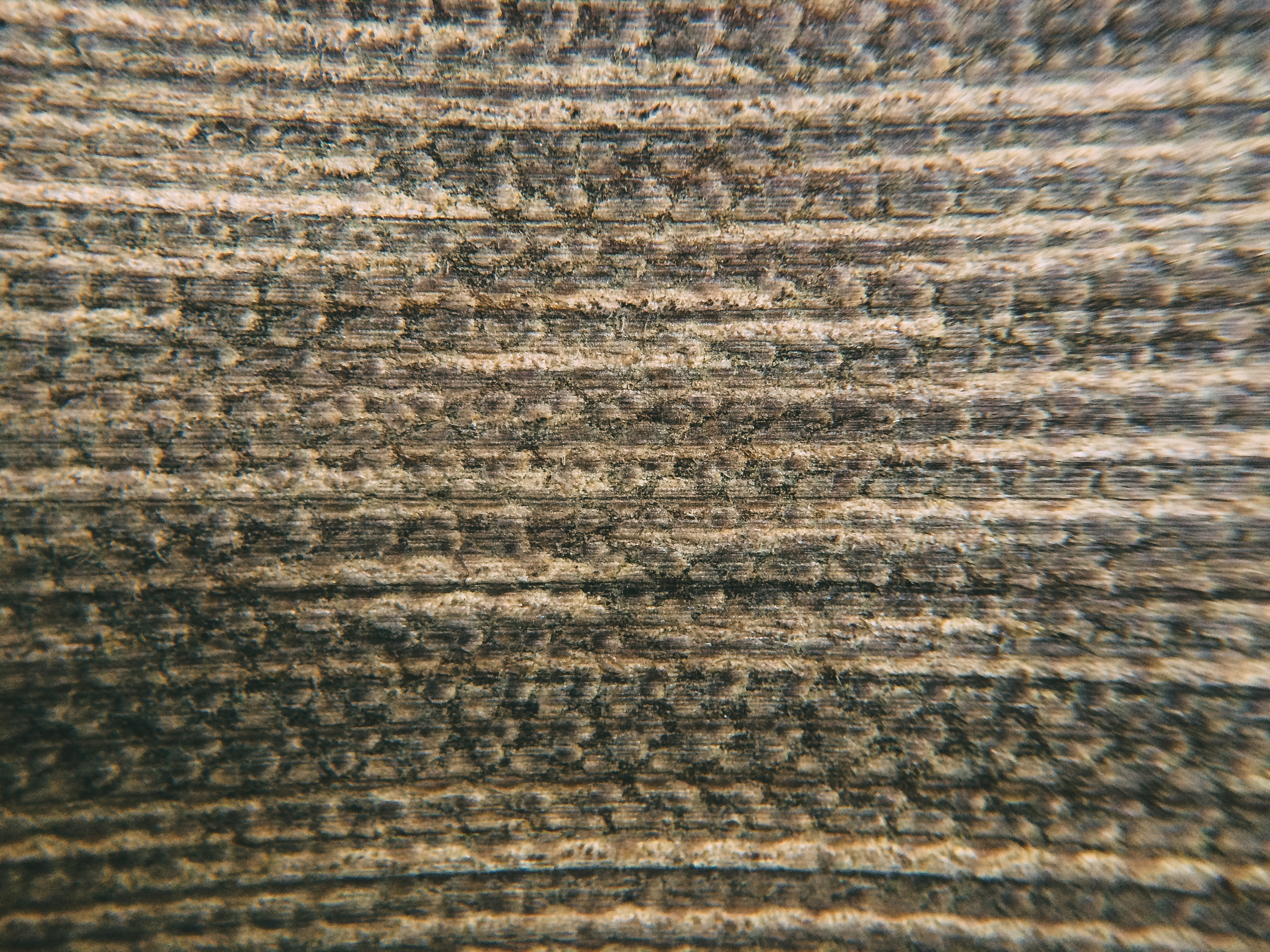

Raw Materials For Micarta

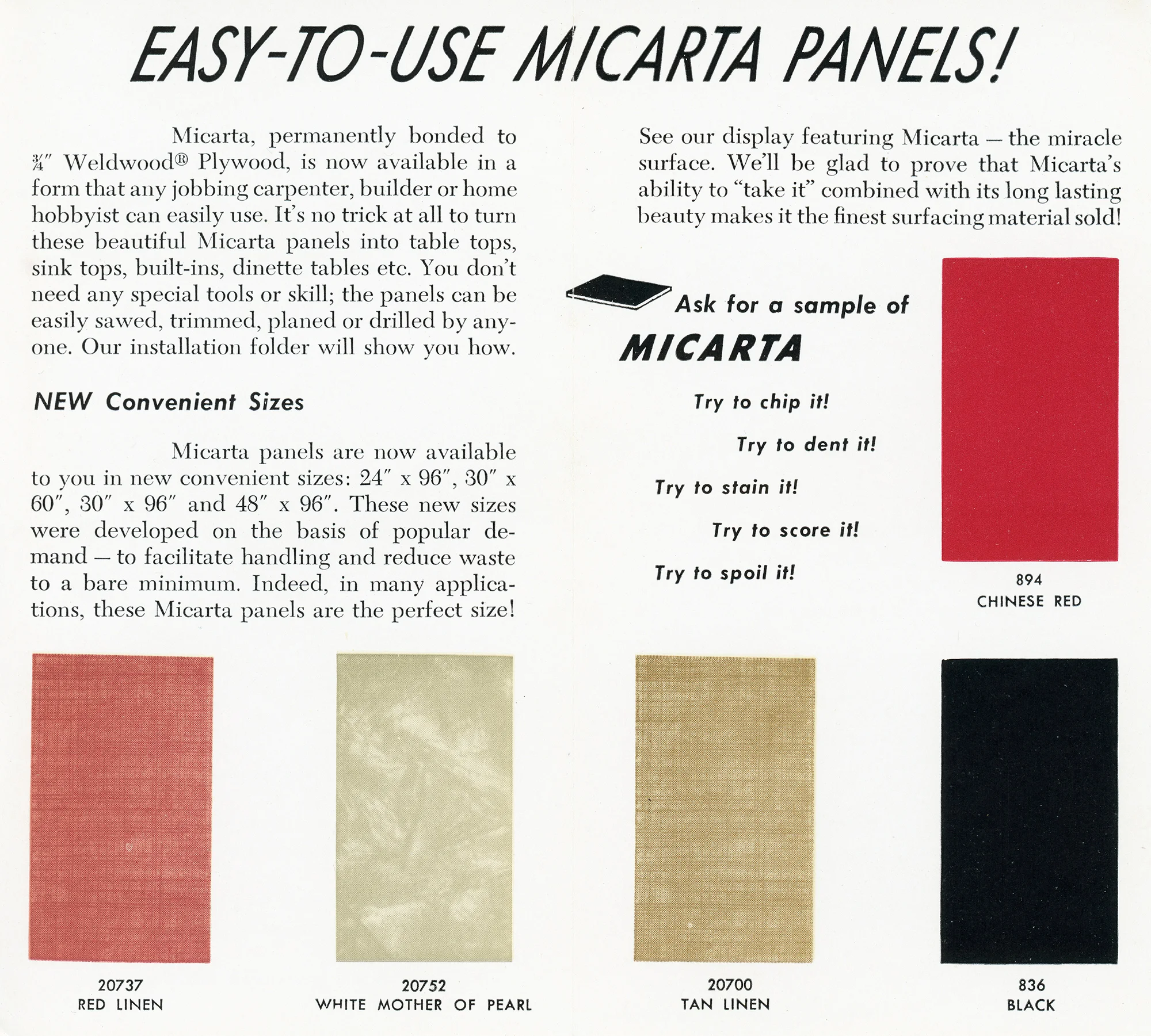

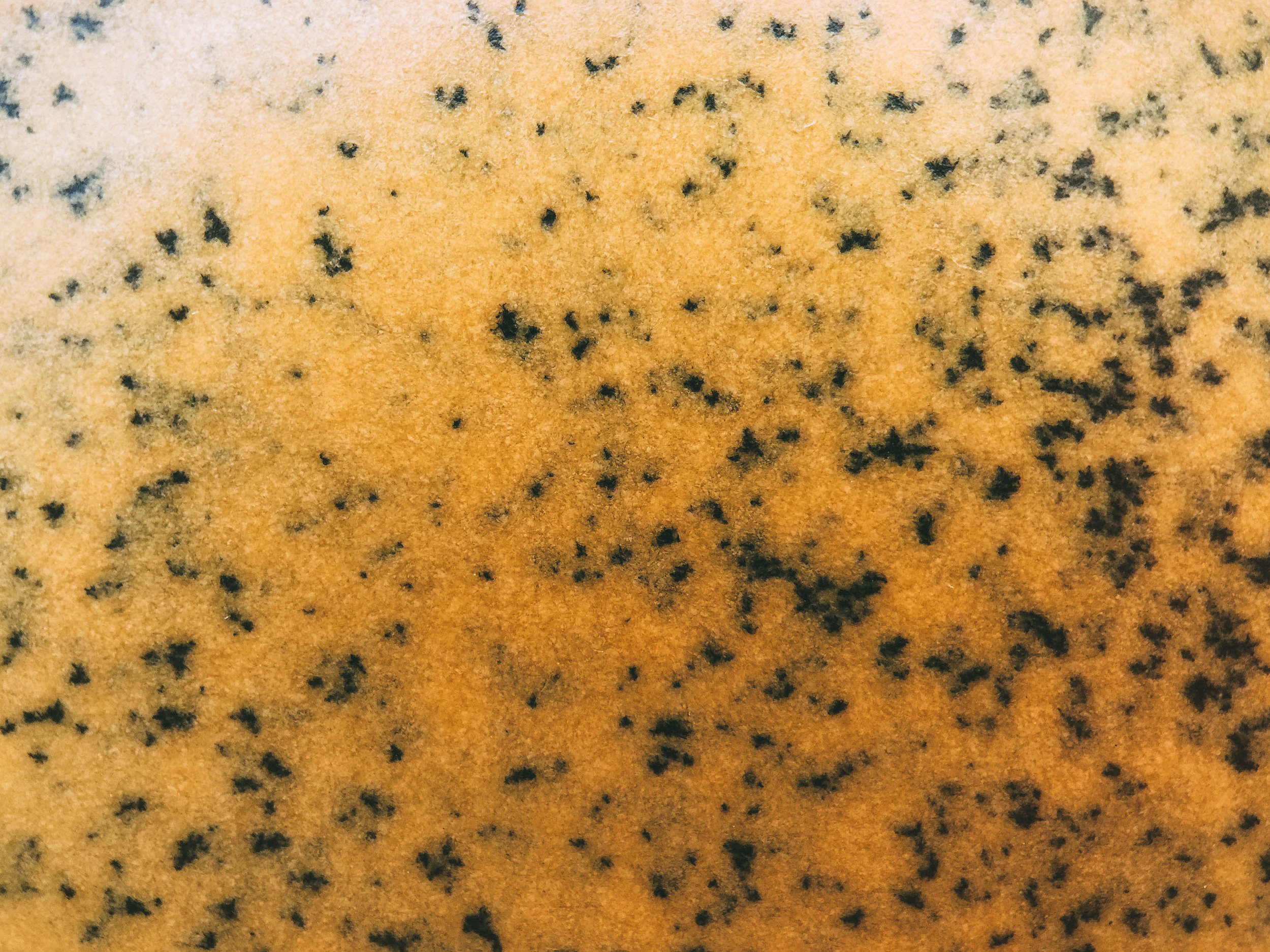

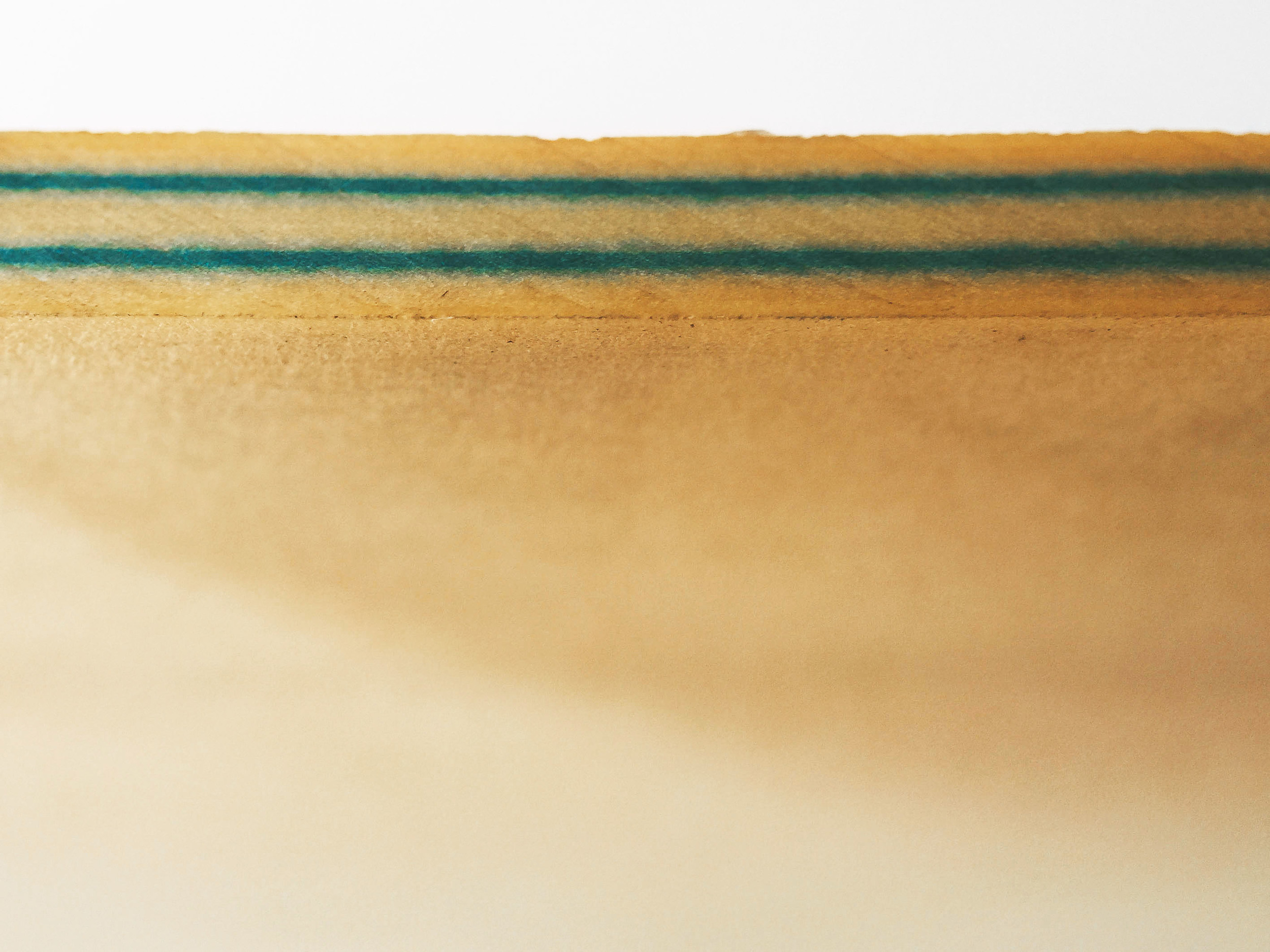

At the base of the drying towers, impregnated brown kraft wrapping paper comes from the drying tower after being dipped twice in a synthetic resin bath. Cut into sheets, this paper will furnish backing material for Westinghouse Micarta table tops, refrigerator linings, kitchen wall paneling and many other things.

Drying Towers In The Westinghouse Micarta Plant

Unwinding from rolls at the bottom of the sixty-foot towers, paper or cloth strips run through three or four baths of artificial resin, passing over rollers at the top of the tower between each dipping to insure complete drying. This is the first step in making this type of plastic.

Molding, Pressure & Heat

Table with rollers facilitates removal of a cured sheet of Micarta, still between the press plates, from a multi-opening press.

For refrigerator door liners, an 8-opening press is used. Flexible hose carries steam and cold water to each platen.

This hydraulic hot molding press converts treated sheets of paper into 20 laminated plastic (Micarta) plates 4’ x 8’. Pressure, temperature and time are accurately controlled. While this batch is baking, the operator prepares a new batch for the next molding cycle.

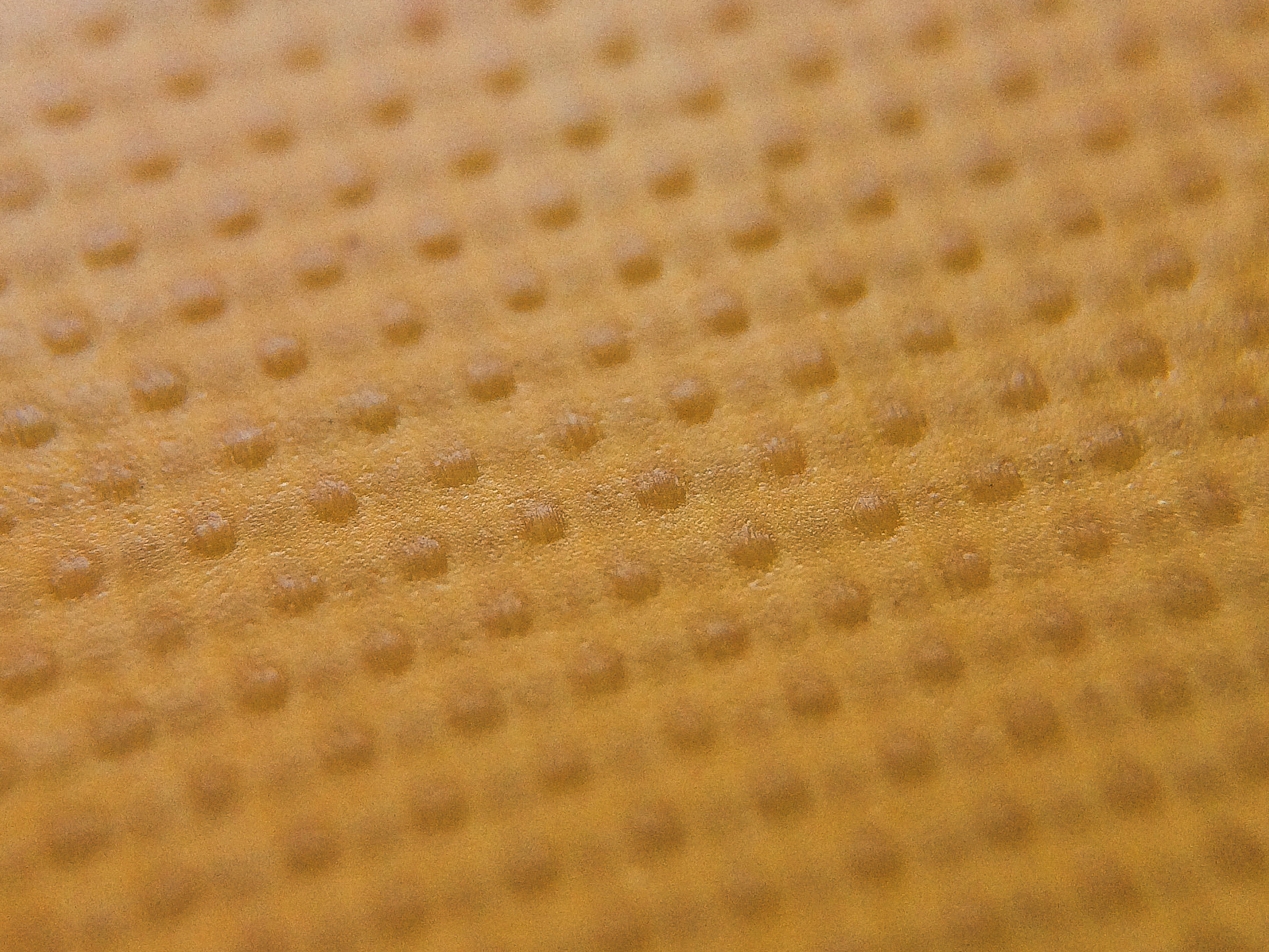

Loose Sheets of Paper Micarta

Heat and 150,000,000 pounds of pressure on these fourteen loose sheets of paper will produce a hard, white, waterproof plastic panel for the inside of a refrigerator. Next the polished steel plate at the bottom will go a sheet of white material resembling wall paper. On top of this will go a number of sheets of brown wrapping paper impregnated with synthetic resin, after which it will go to the moulding press. Westinghouse Micarta is also used for table tops, wall coverings and hundreds of other purposes.

Micarta truck wheels are produced by molding macerated material in positive molds in a compression plate.

High-pressure laminates may be milled with standard high-cutterspeed milling cutters, which are often carbide tipped.

Refrigerator door panels are an important application of Micarta high-pressure laminate, which is light and a very good insulator.

Even a Blowtorch Can't Hurt It!

Dramatically illustrating the flame-resisting qualities of a new plastic/glass panel for electrical control boards on vital Navy ships, a worker at the Trafford Works Micarta Division of the Westinghouse Electric Corp. applies the hot flame of a blowtorch to a specimen of the new material. Known as glass melamine Micarta, the panel board material produces nitrogen, a chemical that smothers flames when heated.

Micarta used for radio-phonograph housing looks like real mahogany.

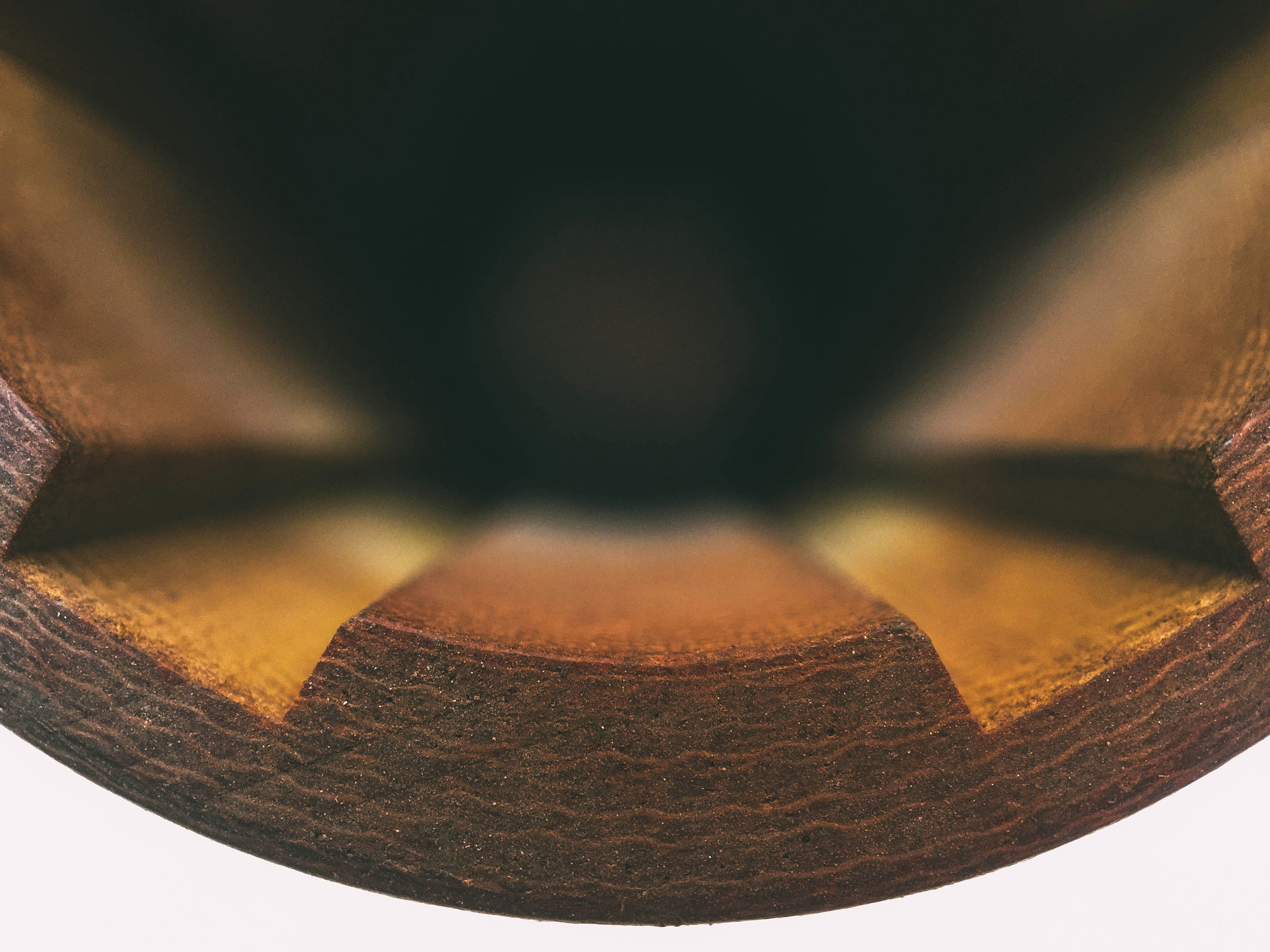

Resistance to moisture and chemicals leads to wide use of laminates in textile processing. This Micarta spinning bucket is strengthened by stainless steel reinforcement.

June 9th 1944 — Both destruction and construction are necessary to the advance of science and industry, according to Eugene R. Perry, research engineer of the Westinghouse Electric and Manufacturing Company. Ordinarily a chemical laboratory is busy separating materials into their component elements in order to analyze their composition. Perry is experimenting with a new synthetic resin, creating a combination which may point the way to a new and improved insulating material. An unlimited number of incidents may be added to the combination in the flask through two tubes at the right. A definite degree of heat is applied to the flask while the picture is stirred by a vertical shaft driven by a motor on the bench back of the apparatus. At the left is an ice water circulator which cools the reflux condenser, the large tube in the left clamp. Perry explains that this laboratory set up makes it possible to create any of the synthetic resins, to change old formulas and devise new ones in the constant effort of science to improve the materials and products of industry.

New Plastic Used For U.S. Warplanes

Friday, June 9th 1944 New York, N.Y. — Eugene R. Perry, manager of the Micarta Department of the Westinghouse Electric & Manufacturing Company, demonstrates a new plastic which can be formed into complicated shapes in much the same way metal is molded. A thin sheet of the material here heated to the softening point in a dielectric heating unit; then is removed and placed in a mold for pressing the desired shape. Called Micarta 444, the new plastic is being used on U.S. warplanes for wing-gun ammunition feeds, ejection chutes, aviators’ chart cases and scores of other applications. Mr. Perry described the plastic today to more than 100 science writers, newspapermen and trade-paper editors attending a luncheon at the Waldorf-Astoria.

Bottled Cloud For Bomber Insulation Tests

With liquid air and warm water, Research Engineer Arthur M. Stiles manufactures a cloud at the Westinghouse Research Laboratories to test insulating materials for the electrical systems of new bombing planes. Such artificial clouds are easily introduced into the sealed flasks known as altitude chambers where insulating materials can be tested for electrical performance in the presence of clouds and other atmospheric conditions. Even a small snow storm can be reproduced, because when the flask containing the baby cloud is cooled below the freezing point, tiny snow flakes are precipitated onto the material under test.

'Oven-Refrigerator' Tests Strength of Plastic

This combination oven-refrigerator that varies temperatures from 50 degrees below zero to 200 degrees above has been constructed at the Westinghouse Research Laboratories to test the strength of Micarta plastic used in making engine gears and aircraft parts. Frank Cassel, Westinghouse research engineer, is shown measuring the dimensions of a Micarta test piece in the oven-refrigerator before beginning a “fatigue” test. This Micarta stock, along with a similar one to its left, will be vibrated up and down 15 times every second, day and night for as long as three months. While one end of the plastic stick is held stationary, the other end is moved up and down rapidly by the rotating arm and wheel. The amount of load applied and changes in the flexibility of the plastic are measured by the wire resistance “strain gauge” at the stationary end of the vibrator. Cooled by dry ice and heated by electric coils, the oven-refrigerator provides extremes of cold and heat to aid in the development of plastic equipment that gives maximum performance at any working temperature.

This machinist at the Westinghouse research laboratories in Pittsburgh isn’t contributing to the snow and ice of the winter. Instead, he’s fashioning a plastic model which duplicates the stresses a large pressure vessel will undergo. These stresses, frozen into the model are studied under polarized light.

The Micarta Division

The Micarta Division at Trafford, PA is recognized as the largest plant of its kind in the world. The original plant, erected in 1929, had a total working area of ninety thousand square feet; today the floor space approximates two hundred and sixty thousand square feet. With present facilities, including presses up to 3750 tons capacity, more than one million pounds of material can be produced per month. Enough paper and cloth are need in one year to cover twenty-five thousand miles, or a complete turn around the earth at the equator.

Micarta is a Westinghouse trade-name that covers all of the molded products manufactured by the Micarta Division. It is a plastic material using paper, cotton cloth, wood or fiberglass as filler materials. The fillers are impregnated with a fluid synthetic resin that is composed basically of phenol. When properly compounded with other chemicals this produces a fluid resin that can be changed to a solid by the application of heat. This change from a liquid to a solid is known as polymerization.

The filler materials, after being impregnated, are partially dried, and later cut into sheets, rolled on metal mandrels or chopped into small sizes and molded in steam heated hydraulic presses. Carefully controlled temperatures as high as 350°F and pressures exceeding one ton per square inch are used.

Micarta products are, pound for pound, as strong as structural steel; yet they weigh only half as much as aluminum. The electrical properties are unsurpassed, and the effects of moisture, acid, and alkalies do not impair its usefulness. Ordinary metal working tools are used to machine Micarta into many useful industrial and decorative applications.

Micarta Lighter Than Aluminum

Westinghouse Micarta For Aircraft